How to Choose the Right Pharmaceutical Packaging Machine for Your Business

Pharmaceutical Packaging Machine helps to ensure safe and secure handling of pharmaceutical preparations. This helps to prevent microbial growth and extend the shelf life of the medicine.

Whether it’s blister packs, prefillable syringes, or bottles, packaging automation is helping pharmacies prepare for the future. Offering touch-free service, social distancing capabilities, and increased efficiency, it’s the next step in running a pharmacy.

Tube Filling Machine

The Tube Filling Machine is an automatic, semi-automatic, or manual machine that can be used to fill and seal ointments, creams, liquid medicines like syrups, and other pharmaceutical products in tubes. Its features include a smart temperature control system, high production speed, and the ability to adjust to different sizes of tubes. This equipment is also easy to clean and maintain. Its heavy-duty frame is resistant to corrosion, harsh weather, and other physical destruction.

The main component of a tube filling machine is the tank that holds the product. Its size determines the quantity of product that can be ejected from the tube filler. It can also be adjusted to ensure an accurate amount of liquid is dispensed in each cycle. This is a key feature to look for when selecting a tube filling machine.

Another important feature of this machine is the nozzle that dispenses Pharmaceutical Packaging Machine the product into the tubes. Its design allows for adjustments and can be easily adapted to meet the needs of various companies. This is especially helpful if you need to fill both thick and thin liquids.

A tube filling machine can help you save money by reducing labor costs. Its streamlined process allows you to produce more than one tube per cycle, increasing your profit margins. It also reduces the amount of time needed to set up and operate. In addition, it provides consistent results. This is a major benefit for small businesses that want to compete with larger manufacturers.

In addition to saving time, a tube filling machine can improve the quality of your products. It can prevent errors that may occur during the manual hand-filling process, such as uneven weight distribution. It can also prevent contamination, which is crucial for medical and pharmaceutical products.

Moreover, a tube filling machine is also less expensive than hiring human workers. It is a cost-effective solution for manufacturers who need to package products quickly. Additionally, it helps avoid errors that can be caused by a lack of experience. It can also reduce the risk of environmental contamination, which is often a concern with bottled products.

Liquid Filling Machine

A liquid filling machine is used to package liquid products into various types of containers including bottles, jars, buckets, tins and vials. These machines can also be used to fill solid end products such as powders and granules. These machines can work on either volumetric or quantitative packaging and are often highly accurate. They can also be modified to handle a wide range of container types and sizes.

When selecting a liquid filling machine for your product, it is important to consider the type of product you are manufacturing and its viscosity. Viscosity refers to the resistance of a product to flow and different liquids have different viscosities. Less-viscous products like water flow freely while thicker or high-viscosity liquids require special pumps and valves. Liquid packaging machines are designed to accommodate this difference and many have different viscosity settings for optimal performance.

Another feature of a liquid filling machine is its ability to seal vessels after filling. This is very important in terms of ensuring the safety of the product. A good liquid filling machine can do this using pneumatic pressure or a vacuum pump, which is safer than conventional methods. This type of machine is also much more efficient than manual techniques.

The design of a liquid filling machine is also very important. Some of these machines have a conveyor system that moves the container through a series of stations. This is ideal for companies that manufacture a wide variety of products. It can also help reduce the time it takes to complete a batch of production.

A good liquid filling machine is also able to maintain consistent temperatures, which is crucial for the proper functioning of a liquid product. This is particularly important in the case of chemical-based liquids, where temperature control can prevent unwanted reactions and reduce the risk of contamination.

In addition, a good liquid filling machine should be easy to operate and maintain. This is especially true for new employees who may not be familiar with the machine’s operating procedures. Some machines also have a simple user interface and can be programmed to perform a particular process automatically, without the need for human intervention. This can significantly improve productivity and eliminate errors.

Powder Filling Machine

This type of machine is perfect for a pharmaceutical industry that produces drugs or antibiotics. It helps ensure the stability of the drugs and prevents any changes in the product’s contents. It also protects the product from exposure to harmful bacteria and other contaminants. It also helps Pharmaceutical Packaging Machine save content and time by reducing the amount of manual work that is required. It can also increase the company’s reputation and profitability by ensuring higher production speed. There are several different variants of powder filling machines, and each has its own unique benefits. Some are designed to handle free-flowing powders, while others are built for non-free-flowing products. To choose the best one for your business, consider the following factors:

The size of the nozzle on the powder filling machine is important, as it determines the rate at which the product will be filled. Ideally, the nozzle should be in close conjugation with the mouth of the bottle. This will prevent powder from spilling over the sides of the container and will ensure a clean, accurate fill.

A powder filling machine with a high capacity can produce up to 6000 bottles per hour, and it can handle a wide variety of bottle sizes. Moreover, it is easy to operate and requires minimal maintenance. Furthermore, it has a built-in conveyor system that allows for the quick transfer of powder from one station to another. It also has a stainless-steel frame and a rubber stoppering unit, which makes it suitable for use in many environments.

Powder filling machines are essential for various industries, including food and beverage, chemicals, and agriculture. These machines can be used to fill a variety of different types of powders into containers at a high level of accuracy and consistency. They can also be combined with other types of packaging machinery, such as checkweighers, to optimize the production process.

The Powder Filling Machine by Cozzoli uses a dual-level supply hopper and agitator that provides just the right amount of material of uniform density to each dosing chamber of the filling head to maximize accuracy and repeatability. The patented design also eliminates scraper blades, which could potentially contaminate sensitive, sterile products. It is easy to operate and maintain, and it has no abrading parts within the product contact area.

Bottle Filling Machine

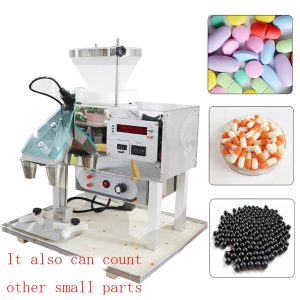

The Bottle Filling Machine is a pharmaceutical packaging machine that allows the filling of liquids into bottles, cans, or other containers. It can also be used to count tablets and capsules, though it is not as accurate as a dedicated tablet counting machine. The machine uses a specialized mass flow meter to measure the amount of liquid, which it then pumps into the bottle. This ensures that each bottle is filled with the correct amount of liquid, and that each bottle is sealed tightly to prevent contamination. The machines come with a number of features to help make them more efficient, including a no bottle no fill vision system that ensures the cycle only begins when the correct container enters the fill zone.

Liquid products differ in viscosity, and these machines are designed to handle a wide range of product types. Piston fillers work well with low-viscosity products, while rotary-valve piston fillers are ideal for very thick products. This type of machine also works well with frothy liquids and can handle products that have chunks or particulates.

Automatic liquid filling machines can run much faster than manual machines, and they are designed to run continuously. They have a number of features to allow them to run smoothly, including conveyor systems, bottle indexing control devices, and servo driven augers. These features are crucial for the accuracy and speed of the liquid filling process, which is why these machines are so popular in the pharmaceutical industry.

Another benefit of these machines is that they can easily be adapted to different bottle sizes. This makes them a great option for companies that produce multiple versions of the same product. In addition, they can be used to create different bottle designs, including squeezable bottles.

Using an automated liquid packaging machine can help you save money and increase your production capacity. These machines are designed to be easy to use and are able to perform a variety of tasks with little human intervention. They are also easy to clean, which makes them a great choice for pharmaceutical manufacturers. In addition, they can help you track inventory and save money on labor costs. They can also help you keep your production process running at a steady pace and prevent waste.