Rolling Machines Save You Time and Money

Rolling machines are used in manufacturing to compress raw metal into a thinner and more uniform shape. They can be mechanical or hydraulic.

Plate rolling machines are the most common form of sheet bending machinery. They are generally electromechanical or hydraulic.

Ease of Use

Using a rolling machine to make joints and cigarettes is much easier than doing it by hand. This can save you time and money, and you won’t have to worry about waste or wasted papers.

A rolling machine also helps you avoid herb waste. When you roll by hand, it can be hard to make a consistent shape, which can result in wasted herbs. However, when you use a rolling machine, it’s easy to ensure that each joint has the same shape and size.

Another benefit of a rolling machine is that it’s incredibly easy to learn how to use. This can help you save time and get better results.

If you’re a beginner, it can be easy to make mistakes rolling machine when rolling by hand. This can be especially true when you’re making a large joint or cigarette. You’ll need to practice and experiment until you get it right, but a rolling machine will help you do this without wasting time.

There are many different types of rolling machines available, so it’s important to know the type that best suits your needs. These machines can vary in terms of capacity and how they adjust to changes in material thickness.

For example, some machines can form steel up to 1-in.-thick, 36,000-PSI-yield-strength metal in multiple passes to a minimum rolling diameter that’s 1.2 to 1.5 times the top roll diameter. This is a lot tighter than some people think, and it’s possible to achieve this even on thinner and narrower materials.

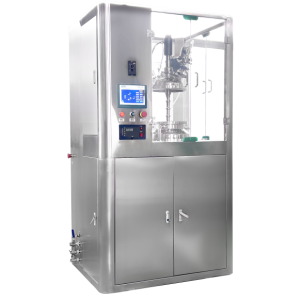

In addition, some models have digital readouts that show the position of the bending roll, so you can make repeat parts easily. They’re also adjustable hydraulically, so you can swivel the top roll to remove a completely formed tube or cone.

Lastly, these machines have an integrated control system that makes them simple to operate. They feature a 15-inch color touch screen display that gives you proportional control over the rotation and movement of each roll.

These models are perfect for newer operators, and they can be used to perform a variety of functions. They can also be customized for specific applications, including pre-bending and cone rolling.

Uniformity

A rolling machine is an industrial tool that uses one or more pairs of rollers to manipulate raw metal, resulting in a desired material thickness and surface shape. These machines can be used to roll a wide variety of materials, from sheet metal to plastics to steel.

For example, a sheet metal rolling machine may be used to produce components such as brackets and frames that support equipment or structures. It can also be used to create curved or cylindrical shapes.

The uniformity of a rolling machine is an important characteristic for ensuring a high level of performance. A rolling machine poorly-rolled part can result in a number of defects, including cracking and tearing.

It can also lead to poor-quality workpieces that require additional processing. These issues can also affect the final product, causing damage to the finished parts and increasing manufacturing costs.

This problem is often caused by the non-uniformity of the strain distribution in the web being transferred under a certain set of tensions. If the distribution is not uniform, a register error occurs in the machine direction (MD or transfer direction) and cross direction of the web, which reduces the accuracy of the printed pattern.

In this research, we studied the effect of a compensation roller on the strain distribution in the MD to minimize this error. We built a three-dimensional finite element model to analyze the interaction between the roller and the web. We measured the strain at the contact points of the roller and the web using load cells.

Our results show that the optimal configuration for the compensation roller is a convex core wrapped in a rubber skin. This rubber skin changes the contact stiffness along the CD on the web when the roller and the web touch, which minimizes the strain deviation in the MD.

The optimized roller can improve the printing precision of fine patterns and mitigate the register error. In addition, the reduced strain deviation can increase the cooling uniformity of the quenching device, thereby improving production quality and optimizing its design.

Convenience

If you are working with metal, a rolling machine is an important tool to have on hand. It can help you to create perfect, uniform joints and reduce the time spent on each individual piece.

Whether you’re new to rolling or a veteran, a quality rolling machine can make your job faster and easier than ever before. A quality machine is also portable enough that you can take it anywhere and use it whenever you need it.

Rolling machines are available in different sizes and offer varying levels of automation, so it’s important to choose the right one for your needs. Some are designed to fit in your pocket, while others require electricity and are much more cumbersome.

Plate rolling machines form cylinders by pulling sheets of metal through a series of rollers that exert pressure on the sheet. They can be used to splinter, bend, and shape a variety of thicknesses and diameters of materials.

Four-roll plate rolling machines have a slightly higher capacity than three-roll models, and are a good choice for production of large, thick plates. They also offer the advantage of allowing pre-bending and tapering to be done immediately following the bending process, which saves time and labor in the long run.

The top and pinch rollers firmly clamp the workpiece during the forming process, so it’s easy to get a straight edge and roundness that meets or exceeds specifications. This ensures that the finished product is free of flaws and defects, and allows the operator to perform other functions without the need to remove and rotate the plate a second time.

Another advantage of a four-roll plate rolling machine is its ability to load the steel plate horizontally, eliminating the need for a crane and ensuring that the next sheet can be loaded as soon as the current one has been rolled. It can also be used to pre-bend both ends of the steel plate, removing many potential hazards that can occur in the material handling portion of the operation.

Brand

A rolling machine is one of the most important tools in the sheet metal maker’s shed. As the name suggests, it’s a machine that transforms raw metal into finished goods such as your favorite pair of kicks or a roof for the home or office. A well-made machine can last a lifetime, if you don’t jack it with your favorite joint and a smattering of spit. It’s a good thing there are so many options to choose from as the number of workers in the industry continues to rise. Some of the best machines in the business are available for rent or purchase on a budget at your local welding and fab shop. The best machines feature a user-friendly operating system, quality control and service personnel who know their stuff.